OLD ARCHIVE FROM 2014 |

Doyle Gobel started his art business using casting as the technique of choice. His art work has always been amazing, but he was having some

trouble with the process and lead times from the foundry where he sent his art. Gobel explains, "I had art shows coming up, I needed to have

product by a certain time, and with casting it was never there on time, because I wasn't that important to them."

That is when he decided to take control of the process himself.

Doyle Gobel started his art business using casting as the technique of choice. His art work has always been amazing, but he was having some

trouble with the process and lead times from the foundry where he sent his art. Gobel explains, "I had art shows coming up, I needed to have

product by a certain time, and with casting it was never there on time, because I wasn't that important to them."

That is when he decided to take control of the process himself.

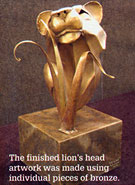

Gobel started cutting pieces by hand and forming them together. He would use masonite for a template and cut the metal by hand. This was a

step above casting but still took quite a bit of time to cut individual pieces. After a few successful art shows, he had a small budget to look into

a new cutting system.

Gobel started to research his options."I looked at every plasma system manufacturer I could find. Price, of course, was a consideration. We

researched as much as we could and finally bought a PlasmaCAM system. To be honest, it wasn't that expensive. One project of mine paid for

the whole system."

Gobel started to research his options."I looked at every plasma system manufacturer I could find. Price, of course, was a consideration. We

researched as much as we could and finally bought a PlasmaCAM system. To be honest, it wasn't that expensive. One project of mine paid for

the whole system."

He cuts using a Hypertherm Powermax 380 and to control the system he uses an old computer he had laying around after an upgrade. The

included software has been great in saving him time, "What I really liked was the software and the fact that you could scan the images in,"

he says. "It automatically determines cut line location. If I want a different size, I just point, drag and increase the scale. I'm able to measure

it right on the screen to see how big it's going to be. It changes the scale of the image instantly."

He cuts using a Hypertherm Powermax 380 and to control the system he uses an old computer he had laying around after an upgrade. The

included software has been great in saving him time, "What I really liked was the software and the fact that you could scan the images in,"

he says. "It automatically determines cut line location. If I want a different size, I just point, drag and increase the scale. I'm able to measure

it right on the screen to see how big it's going to be. It changes the scale of the image instantly."

He also mentions how easy it is to learn the system. "I really didn't have to learn a CAD-type program to run it. I read the book one day,

calibrated the machine the next and started running the day after that."

Now Gobel saves a lot of time using a CNC plasma cutter. Once one sculpture is done, he has all the needed parts programmed into the computer ready to cut. "The time factor is getting better with each piece I produce. Like a bald eagle I produced with a six-foot wingspan. The first one took six months, and the fourth one only took six weeks."

The article below was published by FF Journal magazine July/August 2005 to describe how Doyle Gobel uses the PlasmaCAM in his business:

Published Article

Click on an image to view publication

Other examples from this project

Click on any image to enlarge