OLD ARCHIVE FROM 2014 |

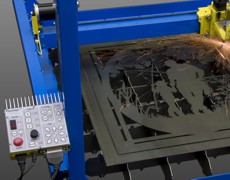

In order to develop the best possible CNC plasma cutting machine, PlasmaCAM has engineered the entire system from the ground up.

Our CNC plasma cutting table, electronics, and CNC CAD/CAM software have all been designed by us - specifically to make plasma cutting easier and higher quality, achieved by the design choices

made on the system.

Every part of the CNC plasma cutting system is designed to work together to give you the best possible results. Instead of using the softer and low grade

aluminum extrusions, we designed the whole frame with quality, cold-rolled steel.

And instead of using the cheaper and less accurate stepper motors,

we use high performance servo motors that provide you with unsurpassed accuracy, acceleration and speed.

Industrial PlasmaCAM CNC plasma cutting systems has the option of Basic and Advanced Digital Height Control and the Z-axis motor is already installed

to give you optimum cutting performance. This allows you to cut nested products without having to use the control box and provides you with

an automated cutting process.

Industrial PlasmaCAM CNC plasma cutting systems has the option of Basic and Advanced Digital Height Control and the Z-axis motor is already installed

to give you optimum cutting performance. This allows you to cut nested products without having to use the control box and provides you with

an automated cutting process.

The CNC cutting machine automatically raises and lowers the torch between cuts and hovers a precise distance over the material during cutting (using arc

voltage feedback). It also synchronizes cutting motion with actual torch firing.

PlasmaCAM CNC cutting tables are designed with high performance servo motors to ensure speed and accuracy. And the issue is not so much speed as

acceleration. In order for plasma cutting to be top quality, you have to keep the torch moving at a very constant speed, even when you go around sharp

corners. If you don't, cuts get ugly and fine details can melt off your pieces.

PlasmaCAM CNC cutting tables are designed with high performance servo motors to ensure speed and accuracy. And the issue is not so much speed as

acceleration. In order for plasma cutting to be top quality, you have to keep the torch moving at a very constant speed, even when you go around sharp

corners. If you don't, cuts get ugly and fine details can melt off your pieces.

The cutting speed on our CNC tables can range from 0.1 to 1000 inches per

minute which means that PlasmaCAM cutting tables are faster than any of our competitors in cutting speeds and the fact that the torch is being

repositioned in between cuts at 1000 inches per minutes reduces production times drastically. The high cutting speed also allows you to cut very small

products. In some of our plasma cuts we go down to 1/6 inch in width on the material for the products.

The PlasmaCAM CNC machines are pre-assembled so they don't require you to build, weld, grind-to-fit, paint, or assemble drive components. Whether

you decide to purchase the DHC2 or the DHC10, the set-up of the machine is easy and supported by instructions through the video manual.

The PlasmaCAM CNC machines are pre-assembled so they don't require you to build, weld, grind-to-fit, paint, or assemble drive components. Whether

you decide to purchase the DHC2 or the DHC10, the set-up of the machine is easy and supported by instructions through the video manual.

The average time of assembling the DHC2 cutting table and setting it up for production is 3-5 hours and the DHC10 averages 5-7 hours.

DHC2 4'x4' CNC Plasma Cutting Table

DHC10 5'x10' CNC Plasma Cutting Table

The revolutionary PlasmaCAM® plasma cutting machines are available in two sizes:

| Model | DHC2 | DHC10 |

| Power Required | 115/230 VAC, 50/60 Hz, 10 A | 115/230 VAC, 50/60 Hz, 10 A |

| Can Power Off same Circuit as Computer | Yes | Yes |

| Weight | ||

| Shipping Weight |

385 Pounds (175 kg) |

700 Pounds (317 kg) |

| Ships in a single crate. | Yes | Yes |

| Dimensions | ||

| Width x Depth x Height |

69" x 65" x 90" (1.75 m x 1.65 m x 2.29 m) |

133" x 82" x 97" (3.38 m x 2.08 m x 2.46 m) |

| Table Surface Height. |

33" (0.84 m) |

33" (0.84 m) |

| Cutting Capability | ||

| Cut Area |

48½" x 48½" (1.23 m x 1.23 m) |

60½" x 120½" (1.54 m x 3.06 m) |

| Material Thickness |

1¼" Max (3.175 cm) |

1¼" Max (3.175 cm) |

| Material Weight |

2,000 Pounds Max (910 kg) |

2,000 Pounds Max (910 kg) |

| Speeds (per minute) | ||

| Cutting/Rapid (X/Y Axes) |

0.1" to 1,000" (2.54 mm to 25,400 mm) |

0.1" to 1,000" (2.54 mm to 25,400 mm) |

| Raise/Lower (Z Axe) |

4" to 104" (101 mm to 2642 mm) |

4" to 104" (101 mm to 2642 mm) |

| Resolution | ||

| X/Y Axis |

0.005" (0.127 mm) |

0.005" (0.127 mm) |

| Z Axis |

0.002" (0.0508 mm) |

0.002" (0.0508 mm) |

| Digital Height Control | ||

| Digital Height Control | Optional | Optional |

| Advanced Digital Height Control | Optional | Optional |

| Advanced Machine Controls | ||

| Advanced Design Software | Optional | Optional |

| Advanced Machine Control | Optional | Optional |

| Automatic Shape Nesting | Optional | Optional |

| Every machine is built to the highest quality control standards | ||