OLD ARCHIVE FROM 2014 |

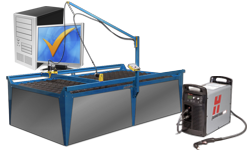

The PlasmaCAM system is not a kit and doesn't require you to build, weld, grind-to-fit, paint, or assemble drive components. You don't have to fabricate any framework or supporting structure to have a functioning machine. We provide a total system that has been manufactured, tested and expertly crated for shipment. The whole design has been carefully engineered, tested and refined over the course of many years and precision fabrication and quality control ensure that all the parts fit. All you need extra is a Computer, Compressed Air and a Plasma Cutter

The PlasmaCAM machine holds a standard plasma torch that can also be used for hand cutting. Virtually any plasma cutter can be used, although performance can vary widely

across different brands. Carefully check into a unit before you buy it, and call us for assistance. Our high-performance plasma cutters give you the best possible cut quality

when used with our machine and include all the parts you need.

Choose a unit based on the thickness of metal that you want to cut. A larger unit will give you more flexibility and the ability to cut metal faster, because it will still be able

to cut thin metal. Note that plasma cutters require compressed air and adequate electric service (typically the same amperage as the cutter's rated output).

PlasmaCAM offers a variety of Plasma Cutters ranging from 30 Amp (cutting 5/16 inch metals) to 105 Amp (cutting up to 1¼ Inch Metal)

Click on the plasma cutter you're interested in for details:

The PlasmaCAM machine connects to virtually any Windows-based computer through a parallel port (printer) cable. PlasmaCAM can deliver a high-speed personal

computer that comes with a 17-inch monitor, a parallel port, and a 6-foot parallel port cable.

If you already have a computer available, you can check the requirements here:

PlasmaCAM CNC plasma cutting machine cutting pipe using optional attachment. Tube outside diameter must be between 1½ inch and 13½ inch.

Tubing length is unlimited through indexing. Pipe cutter cuts artistic designs, letters, or mechanical notches for welded pipe junctions. Software includes

advanced pipe notching features for welded pipe junctions.

PlasmaCAM CNC plasma cutting machine cutting pipe using optional attachment. Tube outside diameter must be between 1½ inch and 13½ inch.

Tubing length is unlimited through indexing. Pipe cutter cuts artistic designs, letters, or mechanical notches for welded pipe junctions. Software includes

advanced pipe notching features for welded pipe junctions.

Pipe Cutting Attachment

Fits onto the machine and cuts round pipe and tubing. Shapes can be cut either within the pipe or on the ends. The outside diameter must be between

1½ and 13½ inches, and long lengths can be cut through indexing. (30 minutes of setup time is required to change the machine from cutting sheet to

cutting pipe and vice-versa.)

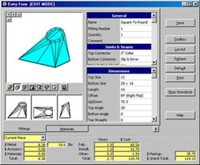

Make high-quality ducts, fittings, flanges and brackets for custom mechanical jobs. The optional software automatically designs

3-dimensional custom parts based on your dimensions, materials and other preferences.

Make high-quality ducts, fittings, flanges and brackets for custom mechanical jobs. The optional software automatically designs

3-dimensional custom parts based on your dimensions, materials and other preferences.

The software package allows you to create standard parts for HVAC, roofing, piping, and heavy plate industries. The comprehensive library has round,

rectangular, oval and combination fittings and uses industry standard gauges, connectors, seams, lining and vanes.

It applies the SMACNA standards, pressure gauge classes based on size, and bend setbacks based on metal thickness.

You will get fully customizable parts

where you can change dimensions, offsets, angles, size, shape, or construction. It shows previews, weight, square footage, scrap and costs before the part is made.

Keep production running efficiently with printed reports, materials lists, and production labels and process multiple fittings at once for any number of jobs and zones.

You will get fully customizable parts

where you can change dimensions, offsets, angles, size, shape, or construction. It shows previews, weight, square footage, scrap and costs before the part is made.

Keep production running efficiently with printed reports, materials lists, and production labels and process multiple fittings at once for any number of jobs and zones.

PlasmaCAM does not carry air compressors as a product, since you can buy these inexpensively in any decent home appliance store.

Recommendations for Air Compressor for the Plasma Cutter:

We recommend an air compressor with 6.7 CFM output, 90 PSI and at least a 30 gallon tank. It is very important to have a dry air supply,

so use dryers, etc. that will be effective! This will make a big difference in cut quality and consumable life.

Plasma cutting generates fine metal dust that can be controlled in various ways. Click on the pictures to see how two of our customers handled it. Below you can find our recommendations:

For significant use, we recommend making a downdraft system. This pulls dust down and outside. The DesignEdge® software includes the designs of

panels you can cut and install to build a downdraft table. We recommend at least a 3500 - 5000 CFM fan for this. You will need to provide the fan

and ducting to move the air outside.

For significant use, we recommend making a downdraft system. This pulls dust down and outside. The DesignEdge® software includes the designs of

panels you can cut and install to build a downdraft table. We recommend at least a 3500 - 5000 CFM fan for this. You will need to provide the fan

and ducting to move the air outside.

You can also use a water table.

This captures a lot of the dust in water without requiring a fan or a flow of air to the outside. Building a water table is simple. (plans in

the DesignEdge software) However, we don't recommend it because it makes a mess, rust, and is not as effective as a down-draft system.