Digital Height Control

Why DIGITAL HEIGHT CONTROL²™ is Essential

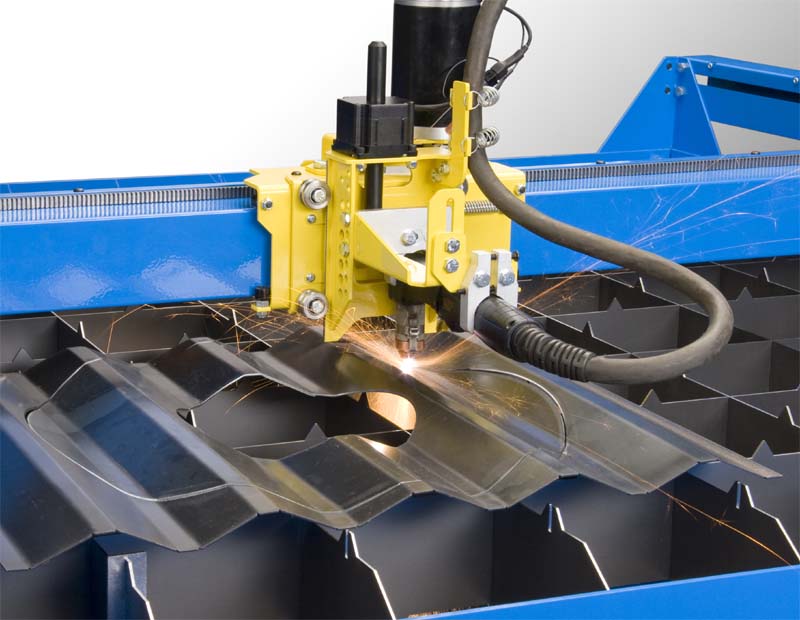

- High quality plasma cuts are achieved by controlling the height of the torch with arc voltage feedback. The cutting tip hovers a precise distance above the metal, moving up and down to follow variations in the sheet.

- The material is automatically sensed before each cut to set the exact pierce height.

- The system knows when it's crossing an existing kerf or when the cut speed slows down, and it automatically keeps the height control from reacting and diving into the material.

- The torch raises and lowers between cuts to avoid obstacles. Tip hangup and collisions are further minimized due to the material sensing and careful control of torch height.

- At the start of each cut, the system waits until plasma cutting is detected before beginning motion (instead of just waiting for a set time delay). It also stops motion if plasma cutting unexpectedly terminates. This means more consistent, automated cutting.

- The careful control of the torch height greatly extends cutting tip life.

- All height control functions are integrated and controlled by the PlasmaCAM DesignEdge™ software - providing automated operation that is easy to adjust.

The DIGITAL HEIGHT CONTROL²™ on PlasmaCAM machines, makes it possible to cut metal such as this corrugated sheet.