The CAD features of our software allow you to quickly draw and layout

precise geometric shapes like these dirt bucket parts. The bucket ears

were drawn in less than 1 minute and cut from 1” material –

without any grinding. Note the smooth cut.

|

Designed

specifically for plasma cutting, the PlasmaCAM™ software

is included with the machine. This complete CAD/CAM program not

only creates designs, it also runs the machine (no other software

is needed). The program is Windows-based and very easy to use.

PlasmaCAM™ is the only CNC system that lets you work directly with the images

that you want to cut, eliminating any need for machine

programs, layout  drawings, or metal patterns. The software controls

and tracks the machine in real time, providing a visual link

between the designs on-screen and the shapes being cut. This

makes laying out and cutting parts easier than ever!

drawings, or metal patterns. The software controls

and tracks the machine in real time, providing a visual link

between the designs on-screen and the shapes being cut. This

makes laying out and cutting parts easier than ever!

|

| |

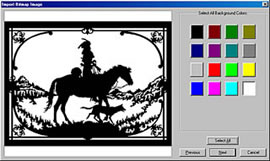

This hand-drawn art scene was scanned, processed by the PlasmaCAM™ software, cut out of metal, painted and framed.

|

Jobs that used to take all day can now be done in just minutes.

Save time and money with PlasmaCAM™!

|

-

Directly read and convert scanned

pictures and hand-drawn artwork. PlasmaCAM's™ unique,

automatic functions remove defects and turn images into paths (vectors)

that can be cut by a machine.

-

Add artistic lettering to your

designs using various True Type fonts.

-

Transfer files to and from

other programs in many file formats, allowing you to use designs

from other sources.

-

Quickly and precisely draw geometric

shapes and/or modify designs.

-

Measure part designs to see

dimensions and how long parts will take to cut.

-

Zoom in for a close

look at a particular area while you work.

-

Resize, rotate, make copies, nest parts and

much more!

-

Automatically prepare complex designs for

cutting in one step. This adjusts the shape for the torch

kerf, adds lead-in pierce points, and reorders holes to be

cut in order before the perimeter.

-

View and change the order

in which any piece is to be cut, if desired.

-

Easily

place parts on screen exactly where you want them cut

from the material. The computer screen shows the locations

of your parts, material and torch.

-

Immediately move

the torch to any point on the cutting table – just

click with the mouse.

-

Jog and shuttle the torch around using

the controller – the

computer screen simultaneously shows where the torch tip is in

relation to your drawing.

-

Select a part on screen to cut it. The

torch tip cursor moves around the part on-screen

during cutting.

-

You can pause the machine at any time

and resume where you left off. This lets you change settings

or even trace back along the cut path to re-cut an area.

-

Automatically

cut a large part (up to 20 ft. long) in one piece. The

machine pauses after cutting each section so you can index

the material and resume cutting.

-

Save time when cutting large

parts by lining up any straight sides to sheet edges

(instead of cutting them).