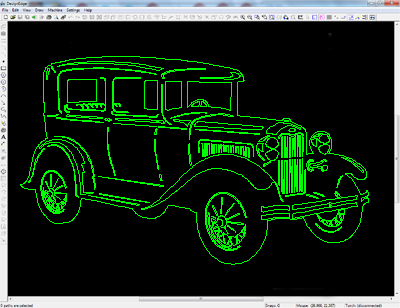

The PlasmaCAM machine cuts flat shapes out of metal with incredible precision and speed.

“DesignEdge – the most user-friendly program for CNC cutting. If you can move the mouse, you can use this software”

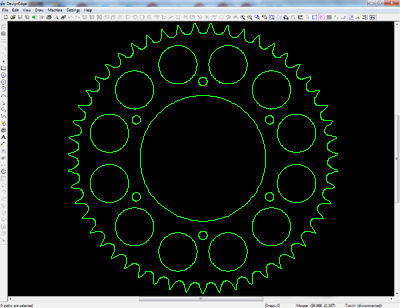

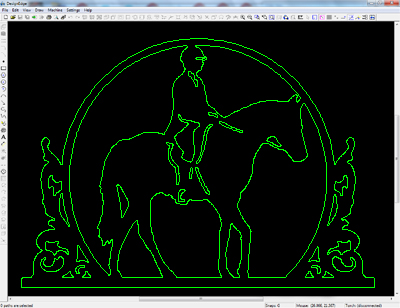

Developed by PlasmaCAM, Inc. specifically for plasma cutting, DesignEdge® is the most valuable part of the system. You can quickly create impressive designs, easily importing and reproducing almost any shape from scanned images, computer fonts, and common drawing programs.

PlasmaCAM is designed, engineered, and manufactured in Colorado City, Colorado USA. We pride ourselves in our quality product, proprietary software, and unmatched customer service that is available to all PlasmaCAM owners.

We design integrated electronics and software for plasma cutting rather than piecing together cumbersome, multi-purpose components from China and other third parties. This gives you a more reliable system that takes less time to learn and use. Our DesignEdge® software is the most powerful and user-friendly software available for CNC plasma cutting.

PlasmaCAM machines can cut at 1000 inches per minute and accelerate at 1G. Our carefully engineered servo control system provides more intricate cutting with higher accuracy than slower stepper motor-based systems.

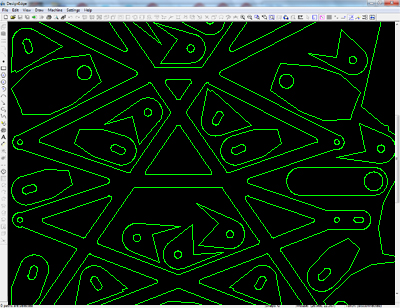

You can engrave fine detail, cut round pipe, cut wood and plastic, and even create 3D shapes with our optional attachments. Our patented Digital Height Control™ gives you top-of-the-line cuts in uneven material. Our DesignEdge® software can automatically nest shapes to use material more efficiently, and you can design and cut HVAC fittings.

PlasmaCAM machines have cut over 1 billion feet of metal over the last 22 years. PlasmaCAM is the name you can trust both now and into the future.